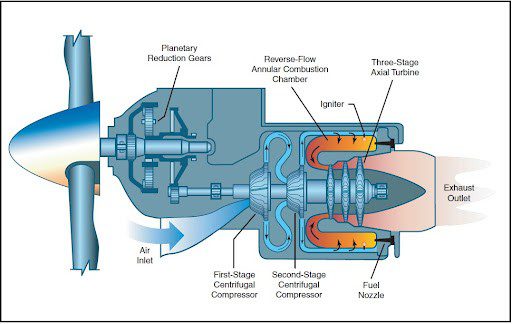

A turboprop engine is a variant built on top of a turbojet engine that uses a turbine to generate shaft power to run a propeller. These engines are a mixture of the new gas turbine propulsion and the old reciprocating engine propulsion. A turboprop engine can also be thought of as a turbo-shaft engine, in which the propeller is linked to the shaft via a reduction mechanism.

Also Read: What to Look For in Feedback Engine Software Collecta

The nozzle, gas turbine, combustion chamber, compressor, reducer, and propeller are the major components of the turboprop engine. In this engine, 80%-90% of the total drive thrust generates through the gas turbine, and the rest is generated through the gas expansion in the nozzle. Therefore, the power produced by the gas turbine is used to drive the propeller and the compressor, but with turbojets, the turbine power is only utilized to run the compressor and the ancillary units.

A gas turbine runs a propeller via a reduction gear unit and discharges in a large quantity of air. Most of the air entering the propeller passes by the duct around the engine and the remaining is further pressurized by the compression of the diffuser piston.

The burner uses to burn the fuel and the resulting hot gas expands inside the turbine and finally in the nozzle. The total thrust generated is the summation of the thrust forces generated by the propeller and the nozzle. In contrast to the turbojet engine, the turboprop engine also most widely uses in commercial and military aircraft because it consumes low fuel and high flexibility to operate at moderately high speeds.

What does turboprop maintenance cost?

A turboprop engine is also known as the low cycle fatigue component. The cost of owning a turboprop engine is lower than the cost of a turbofan engine.

However, the cost of overhauling a turboprop engine for a commercial aircraft is typically between $ 990,000 to $ 300,010 per engine. To manage maintenance costs for turboprop engines, each engine manufacturer (and independent maintenance plan provider Jet Support Services, Inc.) offers a variety of proprietary maintenance plans by those plans. You pay for each flight time.

These timetables cover all regular maintenance, parts, labor, engine transportation, engine credits, and more.

In addition, P & WC offers further professional services for new models, such as digital engine trend monitoring and powerful new oil analysis services. These services are designed to help operators keep their engines running longer by avoiding sudden and costly unforeseen maintenance.

Where can I find turboprop engine maintenance?

Numerous commercial jet turboprop engines from just four engine series are in use around the world. In summary, these four partner brand providers have built a strong and large global network of designated or licensed maintenance providers.

The turboprop engine is used in commercial aircraft is concentrated in four series. This means that many facilities offer maintenance services for each range and some large facilities offer services for all four ranges.

Using Pratt & Whitney Canada as an example, the company’s global service network has grown to include more than 40 proprietary or designated engines and accessories around the world. In the case of PT6A, some of these units provide wing circuit maintenance and mobile repair services, with large facilities serving as designated maintenance facilities.

When it comes to commercial engines, maintenance industry experts recommend that turboprop operators immediately accept cheap engine overhaul offers. These offers can exclude more services than are included and can be annoying for the total of the invoice.

Whenever possible, potential engine repair buyers should inquire about the repair shop they are considering to understand the level of experience of the shop staff and the length of time the shop has been staying. High-quality and reputable shops look forward to such inquiries and respond immediately.

In addition, before signing a contract with a workshop, buyers should ensure that the company can communicate clearly and fairly with its customers to avoid unpleasant surprises.